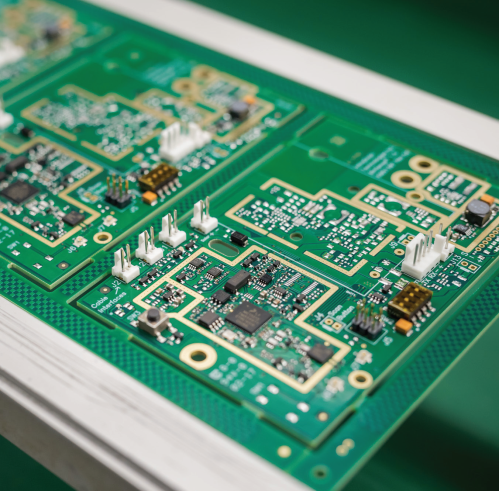

Circuit card assembly features

Manufacturing for diverse industries

Calian excels in building high-quality circuit card assemblies (CCAs) using surface mount and through-hole technologies. We serve a number of diverse sectors, including commercial, defence, agriculture, mining, telecommunications and more. We are able to handle various production volumes and complexities.

Learn about our Surface Mount Technology (SMT)Surpassing expectations with surface mount technology

Exceeding expectations, redefining excellence.

Technical depth and experience

More than two decades of pioneering SMT expertise

- Over 20 years in SMT assembly and active membership in IPC and SMTA

- Involvement in IPC standards development committees and commitment to ongoing industry research

- Focus on new alloys, materials, processes, software and equipment to stay ahead in a rapidly evolving industry

Stringent control process

Ensuring excellence at every step

- Rigorous first-off inspections, including 3D X-ray

- Product thermal profiling to achieve optimal solder joint formation

- 3D automated optical inspection for strict process control and compliance with quality standards

Value-added services

Enhancing capabilities with specialized services

- DRC/DFM analysis using state-of-the-art software tools

- BGA reballing services, including salvage, rework and alloy changes

- Tape and reel processing for bulk parts and advanced non-destructive failure analysis techniques

Certifications and compliance

Adhering to top industry standards for quality assurance

- Compliance with Class 3 IPC standards and in-house Certified IPC Trainer (CIT)

- Certification under ISO 9001:2015 standards

- Part of the Controlled Goods Registration Program (CGRP) and ITAR, with a firm policy against counterfeit goods and commitment to responsible mineral sourcing

Surface mount technology (SMT) specifications

Discover advanced surface mount technology at Calian

Calian provides a state-of-the-art surface mount technology (SMT) assembly line capable of laser marking of PWBs, automated solder paste inspection, 3D automated optical inspection (AOI) and off-line 3D x-ray inspection.

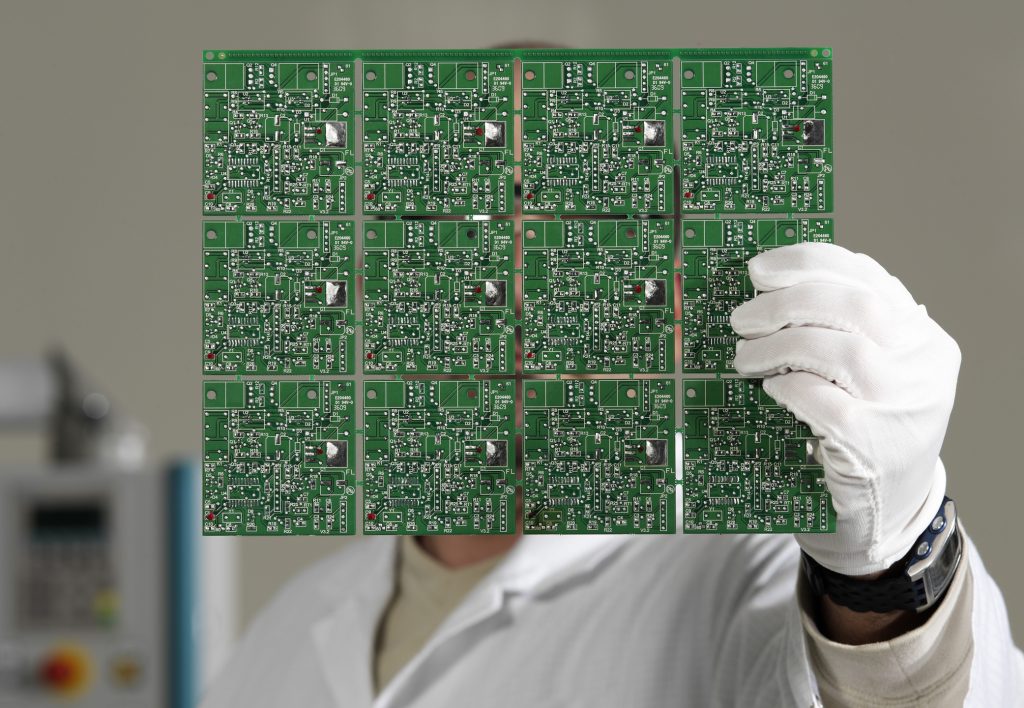

Comprehensive through-hole technology and conformal coating at Calian

Cutting-edge through-hole technology services

By combining the capabilities of programmable selective solder machines with the expertise of skilled assemblers, we achieve high-quality through-hole soldering with efficiency and great accuracy.

Automated selective soldering machines are used to precisely solder through-hole components onto the CCA’s, whether it is a legacy product or a new design. Some of the benefits of this method include a lower risk of damaging sensitive components and the ability to solder complex CCA assemblies with high precision.

Advancing conformal coating solutions

Calian is adept at safeguarding circuit card assemblies designed to operate in harsh environments or challenging conditions—protecting them from corrosion, chemicals, dust and debris.

Our fully programmable selective conformal coating and dispense system is designed for use with both solvent- or water-based coatings.

Full-spectrum in-service support and lifecycle management

Ensuring continued performance and reliability

Restoring and maximizing product lifespan

Restoring and maximizing product lifespan

In demanding environments, our repair and overhaul services are crucial for rapid hardware restoration, ensuring optimal value and extended life for our customers’ products.

Obsolescence management

Proactive strategies for product longevity

Calian proactively manages obsolescence, utilizing advanced tools and engineering expertise to extend component life cycles and keep products operational longer.

Inventory control

Assured material tracking and storage

Calian prioritizes meticulous inventory control, using an MRP system for precise material tracking. This ensures each project’s resources are well-preserved and production-ready.

Configuration control

Diligent maintenance of product standards

Our processes and infrastructure are dedicated to maintaining strict control over product configuration and baselines, ensuring consistency and quality in every build.

Talk to a Calian expert today

Reach out to learn how our innovative solutions can help you solve your most complex challenges.

Social responsibility at Calian

Committed to social responsibility.

ESG—more than a buzzword.

Our vision builds on our mission, values, historical commitment to social responsibility and key competencies. It provides a framework and focus for our activities and corporate communications related to ESG (Environmental Social Governance).

Download ESG report

Your service inspires us.

Proudly welcoming 100+ veterans to our team every year

Their expertise enriches our solutions, and hiring military spouses is our heartfelt way of giving back to the defence community. We’re committed to being there for you, in and out of uniform.

Explore opportunities

Relocating? We’ve got you covered.

4,000+ family members connected with family doctors

Our partnership with the Canadian Forces Morale and Welfare Services ensures that military family members are connected with family doctors, hassle-free.

Learn more

Building a resilient community together.

$650,000+ in corporate giving

We are woven into our community’s fabric, our support extending to renowned organizations and causes. We’re not just about business; we are about building a supportive and resilient community together.

Learn more

Engaging in research that matters.

Our contributions to significant research projects and our focus on environmental safety are unwavering. We’re front-runners in compliance with environmental laws and continually innovate to lessen our ecological footprint.

Learn more

Committed to exceeding expectations.

30+ Indigenous community engagements

With a published Indigenous engagement policy, Calian sets out the framework and guidelines for all Calian business activities while being wholly committed to meeting—even exceeding—the five per cent Indigenous participation requirement on all Federal contracts.

Learn more

Global innovation for connected, safe and healthy lives

Explore our four business units below.