Engineering and technology

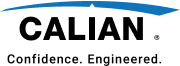

Our facility is equipped with <25μm 3D spatial positioning tools and high-precision metrology equipment, allowing us to achieve tight tolerances and validate those tolerances are maintained during production.

We use high-precision software and lab equipment to verify our designs throughout the product lifecycle to minimize costly redesigns and maximize product performance.

Key capabilities

Material testing laboratory

- Two-sided composite layup and infusion table for monitoring and analyzing resin flow characteristics through any thickness of composite layup

- Ultrasonic test machine for void analysis

- Viscosity, mass and adhesion test equipment

- Environmental chamber

Metrology and precision

- FARO and API laser trackers, FARO arm

- Two 6-axis hexapod positioners

- Custom-built positioning fixturing that maintains tolerances of <10μm

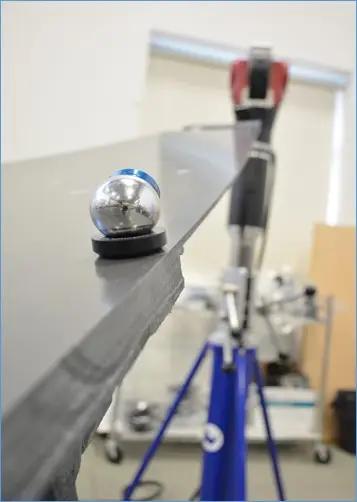

Jig and tooling manufacturing

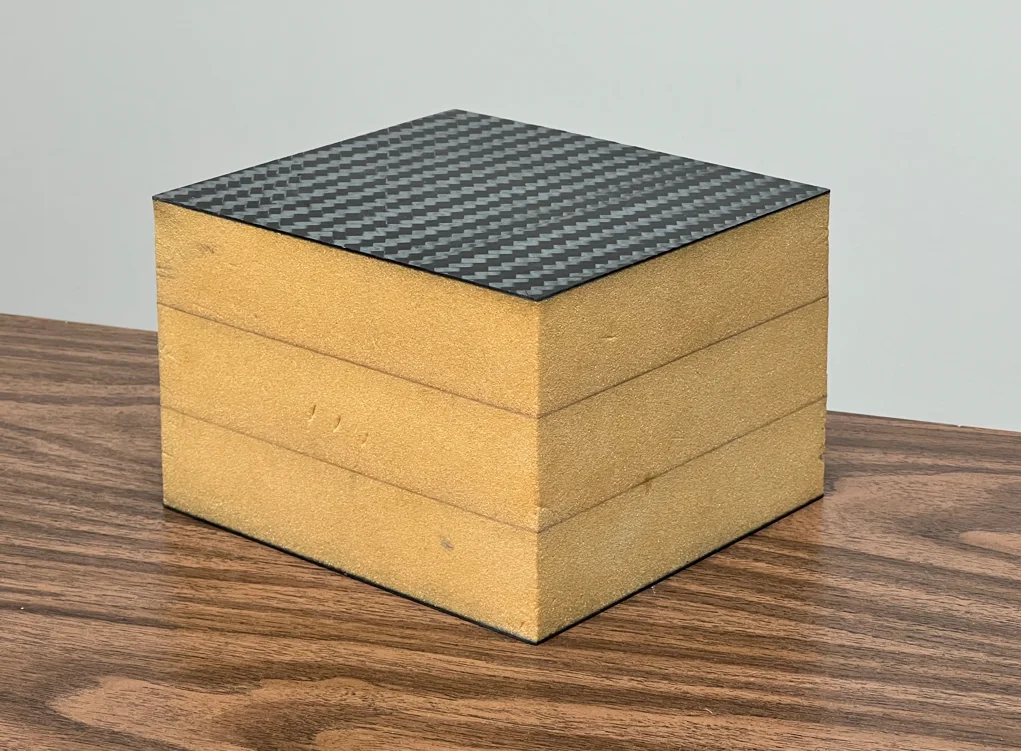

- In-house infused carbon epoxy tooling

- Rapid prototyping and quantification of existing designs

- Custom aluminum, steel and carbon composite jigs

CAD/CAE capabilities

- Industry-leading engineering modeling and simulation package

- FEA for composites using ply-based or zone-based modeling

- Static, dynamic, buckling, thermal, modal and adhesive analyses

- Flat pattern generation

Materials and architectures

We can build to any specifications and design, using your specs or our in-house team of engineers and a variety of materials and architectures.

- Polyester

- Vinylester

- Epoxy

- Methacrylate

- Urethane

- Acrylic

- Silicone

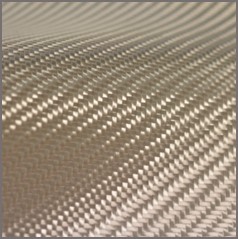

Reinforcement materials

- Carbon fibre

- Fibreglass

- Kevlar

- Metallic meshes

- Foam/plastic core materials

Architectures

- Unidirectional

- Woven

- Braided

- Multi-layer NCS

- Veils

Our manufacturing facility

- Five-ton overhead and one-ton jib cranes

- Large paint booth—14’ x 28’

- Post-cure oven—8’ x 8’ x 20’

- Product-specific post-of-use manufacturing instructions and part quality documentation and tracking

- Established list of qualified machine shop partners

- In-house capability for design and fabrication of customized production jigs

Calian has a reconfigurable manufacturing facility with 34,000 square feet of manufacturing space

Full product lifecyle support

Calian offers composites-specific engineering, metrology and project planning services, from design right through to full component prototyping with the production of final products and assemblies.

Talk to a Calian expert today

Reach out to learn how our innovative solutions can help you solve your most complex challenges.

Social responsibility at Calian

Committed to social responsibility.

ESG—more than a buzzword.

Our vision builds on our mission, values, historical commitment to social responsibility and key competencies. It provides a framework and focus for our activities and corporate communications related to ESG (Environmental Social Governance).

Download ESG report

Your service inspires us.

Proudly welcoming 100+ veterans to our team every year

Their expertise enriches our solutions, and hiring military spouses is our heartfelt way of giving back to the defence community. We’re committed to being there for you, in and out of uniform.

Explore opportunities

Relocating? We’ve got you covered.

4,000+ family members connected with family doctors

Our partnership with the Canadian Forces Morale and Welfare Services ensures that military family members are connected with family doctors, hassle-free.

Learn more

Building a resilient community together.

$650,000+ in corporate giving

We are woven into our community’s fabric, our support extending to renowned organizations and causes. We’re not just about business; we are about building a supportive and resilient community together.

Learn more

Engaging in research that matters.

Our contributions to significant research projects and our focus on environmental safety are unwavering. We’re front-runners in compliance with environmental laws and continually innovate to lessen our ecological footprint.

Learn more

Committed to exceeding expectations.

30+ Indigenous community engagements

With a published Indigenous engagement policy, Calian sets out the framework and guidelines for all Calian business activities while being wholly committed to meeting—even exceeding—the five per cent Indigenous participation requirement on all Federal contracts.

Learn more

Global innovation for connected, safe and healthy lives

Explore our four business units below.