Caractéristiques de l’assemblage des cartes de circuits imprimés

Fabrication pour diverses industries

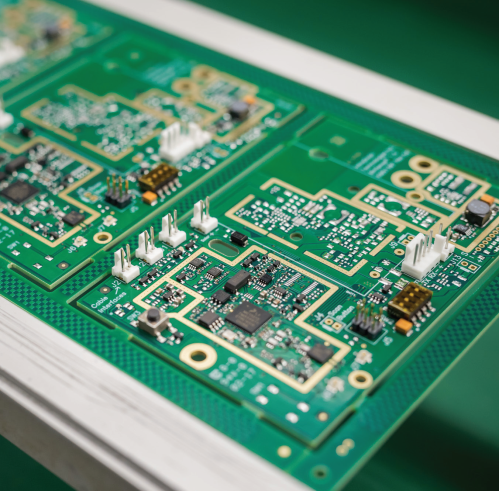

Calian excelle dans la construction d’assemblages de cartes de circuits imprimés (CCA) de haute qualité en utilisant des technologies de montage en surface et de trous traversants. Nous sommes au service d’un certain nombre de secteurs divers, notamment le commerce, la défense, l’agriculture, l’exploitation minière, les télécommunications et bien d’autres encore. Nous sommes en mesure de gérer des volumes de production variés et complexes.

Découvrez notre technologie de montage en surface (SMT)Dépasser les attentes grâce à la technologie de montage en surface

Dépasser les attentes, redéfinir l’excellence.

Profondeur et expérience techniques

Plus de deux décennies d’expertise pionnière en matière de SMT

- Plus de 20 ans d’expérience dans l’assemblage SMT et membre actif de l’IPC et de la SMTA

- Participation aux comités d’élaboration des normes de l’IPC et engagement dans la recherche industrielle permanente

- Se concentrer sur les nouveaux alliages, matériaux, procédés, logiciels et équipements pour rester à la pointe dans un secteur en évolution rapide.

Processus de contrôle rigoureux

Garantir l’excellence à chaque étape

- Inspections rigoureuses à la réception, y compris par rayons X en 3D

- Profilage thermique du produit pour une formation optimale du joint de soudure

- Inspection optique automatisée en 3D pour un contrôle strict des processus et le respect des normes de qualité

Services à valeur ajoutée

Renforcer les capacités grâce à des services spécialisés

- Analyse DRC/DFM à l’aide d’outils logiciels de pointe

- Services de rebouclage de BGA, y compris la récupération, le retravail et les changements d’alliage

- Traitement des bandes et bobines pour les pièces en vrac et techniques avancées d’analyse non destructive des défaillances

Certifications et conformité

Respecter les normes les plus strictes de l’industrie en matière d’assurance qualité

- Conformité aux normes IPC de classe 3 et formateur interne certifié IPC (CIT)

- Certification selon les normes ISO 9001:2015

- Participer au programme d’enregistrement des marchandises contrôlées (CGRP) et à l’ITAR, avec une politique ferme contre les produits de contrefaçon et un engagement en faveur d’un approvisionnement responsable en minerais.

Spécifications de la technologie de montage en surface (SMT)

Découvrez la technologie avancée de montage en surface chez Calian

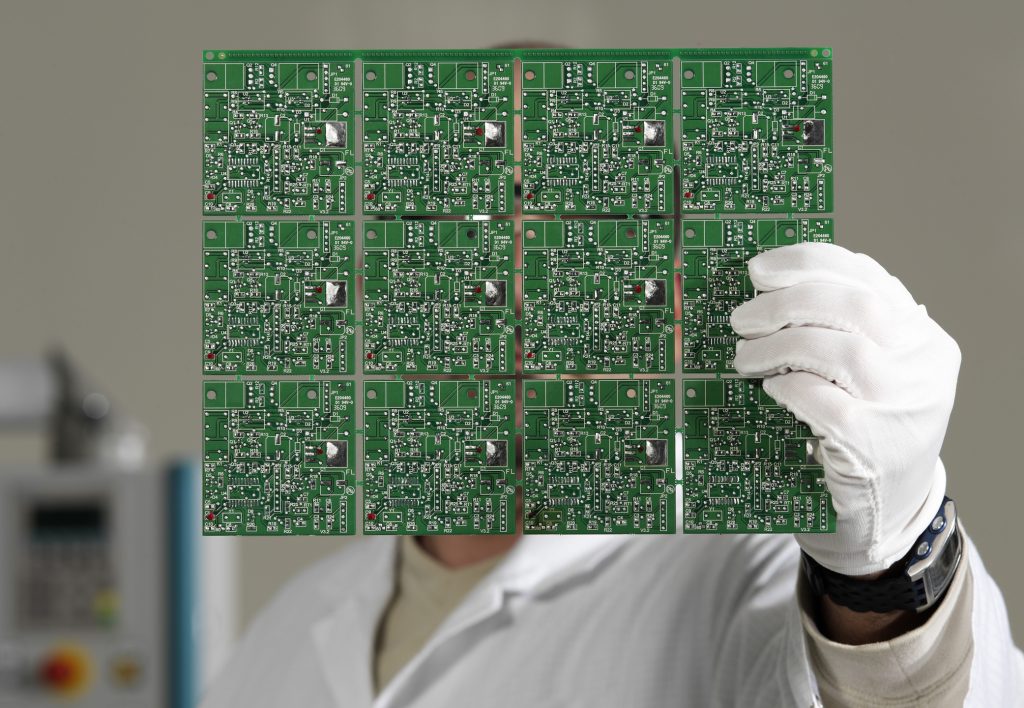

Calian dispose d’une chaine de fabrication pour la technologie de montage en surface (SMT), capable d’effectuer le marquage laser des circuits imprimés, l’inspection automatisée de la pâte à braser, l’inspection optique automatisée en 3D (AOI) et l’inspection par rayons X en 3D hors ligne.

Une technologie complète de trous traversants et de revêtement conforme chez Calian

Services de pointe en matière de technologie des trous traversants

En combinant les capacités des machines à souder sélectives programmables avec l’expertise d’assembleurs qualifiés, nous réalisons des soudures traversantes de haute qualité avec efficacité et grande précision.

Des machines à souder sélectives automatisées sont utilisées pour souder avec précision des composants à trous traversants sur les CCA, qu’il s’agisse d’un produit ancien ou d’une nouvelle conception. Parmi les avantages de cette méthode, citons la réduction du risque d’endommager des composants sensibles et la possibilité de souder des assemblages CCA complexes avec une grande précision.

Faire progresser les solutions de revêtement conforme

Calian est capable de protéger les assemblages de cartes de circuits conçus pour fonctionner dans des environnements hostiles ou des conditions difficiles, en les protégeant de la corrosion, des produits chimiques, de la poussière et des débris.

Notre système de dépose et de revêtement sélectif entièrement programmable est conçu pour être utilisé avec des revêtements à base de solvant ou d’eau.

Support en service complet et gestion du cycle de vie

Assurer la continuité des performances et de la fiabilité

Restaurer et maximiser la durée de vie des produits

Restaurer et maximiser la durée de vie des produits

Dans les environnements exigeants, nos services de réparation et de révision sont essentiels pour une restauration rapide du matériel, garantissant une valeur optimale et une durée de vie prolongée pour les produits de nos clients.

Gestion de l’obsolescence

Stratégies proactives pour la longévité des produits

Calian gère de manière proactive l’obsolescence, en utilisant des outils avancés et une expertise en ingénierie pour prolonger les cycles de vie des composants et maintenir les produits opérationnels plus longtemps.

Contrôle des stocks

Suivi et stockage assurés des matériaux

Calian accorde la priorité à un contrôle méticuleux des stocks, en utilisant un système MRP pour un suivi précis des matériaux. Cela permet de garantir que les ressources de chaque projet sont bien préservées et prêtes à être produites.

Contrôle de la configuration

Maintien rigoureux des normes relatives aux produits

Nos processus et notre infrastructure sont dédiés au maintien d’un contrôle strict de la configuration des produits et des lignes de base, garantissant ainsi la cohérence et la qualité de chaque construction.

La responsabilité sociale chez Calian

Engagé dans la responsabilité sociale.

ESG – plus qu’un simple mot à la mode.

Notre vision s’appuie sur notre mission, nos valeurs, notre engagement historique en matière de responsabilité sociale et nos compétences clés. Il fournit un cadre et une orientation pour nos activités et nos communications d’entreprise liées à l’ESG (environnement, social et gouvernance).

Télécharger le rapport ESG

Votre service nous inspire.

Nous sommes fiers d’accueillir chaque année plus de 100 vétérans au sein de notre équipe.

Leur expertise enrichit nos solutions, et l’embauche de conjoints de militaires est notre façon la plus sincère de rendre à la communauté de la défense ce qu’elle nous a donné. Nous nous engageons à être à vos côtés, que vous portiez un uniforme ou non.

Explorer les possibilités

Vous déménagez? Nous avons tout ce qu’il vous faut.

Plus de 4 000 membres de familles en contact avec des médecins de famille

Notre partenariat avec les Services de bien-être et moral des Forces canadiennes garantit que les membres des familles des militaires sont mis en contact avec des médecins de famille, sans problème.

En savoir plus

Construire ensemble une communauté résiliente.

Plus de 650 000 $ de dons d’entreprises

Nous sommes tissés dans le tissu de notre communauté, notre soutien s’étendant à des organisations et à des causes renommées. Il ne s’agit pas seulement de faire des affaires, mais de construire ensemble une communauté solidaire et résiliente.

En savoir plus

S’engager dans une recherche qui compte.

Nous contribuons à d’importants projets de recherche et nous mettons l’accent sur la sécurité environnementale. Nous sommes les premiers à respecter les lois sur l’environnement et nous innovons continuellement pour réduire notre empreinte écologique.

En savoir plus

Engagé à dépasser les attentes.

Plus de 30 engagements auprès des communautés autochtones

En publiant une politique d’engagement autochtone, Calian définit le cadre et les lignes directrices de toutes ses activités commerciales, tout en s’engageant pleinement à respecter, voire à dépasser, l’exigence de participation de la population autochtone de 5 % pour tous les contrats fédéraux.

En savoir plus

L’innovation mondiale au service d’une vie connectée, sûre et saine

Découvrez nos quatre unités opérationnelles ci-dessous.